Silicera Coat is the optimum coating for those who thinks it wants to impart non-stick and slippage.

No peel strength with adhesive tape !

It has the most suitable non-stick for the prevention of adhesive tapes' or films' adhesion and the improvement of mold releasability.

| Silicone coatings | 0g |

|---|---|

| Fluoropolymer coatings | 51g |

| Silicera Coat 8011 | 0g |

* Peel strength of adhesive tape (Nichiban 405, 6 mm wide) was tested by abrasion testing machine (HEIDON Type 38).

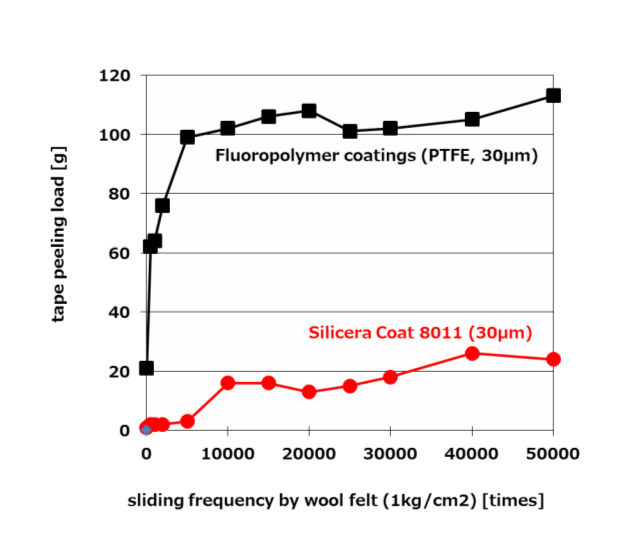

Silicera Coat's coating hardness is 9H, although that of fluoropolymer coatings is 2H.

It achieves the higher hardness than fluoropolymer coatings and raises the durability.

The wool felt was pressed against the Silicera Coat coated test piece with a load of 1 kg / cm 2 and slide, and as a result of measuring the peeling strength of the tape with each number of strokes, the high non-stick property was maintained even after sliding over 10,000 times.

It reduces deformation of substrates due to heat, because the curing temperature after coating is low (100°C~250°C).

It’s possible to impart non-stick to substrates that are worried about thermal deformation.

It can be processed also on CFRP or epoxy resin which non-stick coatings were not available for so far.

| Silicera Coat 8011 | Fluoropolymer coatings (PTFE) | Silicone coatings (thermal spraying required) | |

| Heatproof temperature of coatings | 300℃ | 260℃ | 200℃ |

| Heatproof temperature by non-stick properties | 200℃ | 200℃ | 150℃ |

| Non-stick properties (initial releasability)*1 | 0g | 51g | 0g |

| Non-stick properties (releasability after sliding 5000 times) | 17g | 99g | Unmeasurable*2 |

| Water repellency (contact angle with water) | 100 | 120 | 110 |

| Slippage | △ | ○ | × |

| Standard coating thickness (μm) | 30~50 | 30~50 | 100~200(incl. thermal spraying) |

| Coating hardness | 9H | 2H | Depending on the way of thermal spraying |

| Surface roughness Ra (μm) | 2.0~3.0 | 1.0~1.5 | 3.0~15.0 |

| Heat treatment temperature(℃) | vs metal 100~250℃ |

vs metal 400℃ |

vs metal 200℃ |

| vs non-metal 100℃ |

n/a | n/a |

*1: Peel strength of adhesive tape (Nichiban 405, 6 mm wide) was tested by abrasion testing machine (HEIDON Type 38).

*2: Wool felt was worn away at the sliding test (load 1kg/cm2).

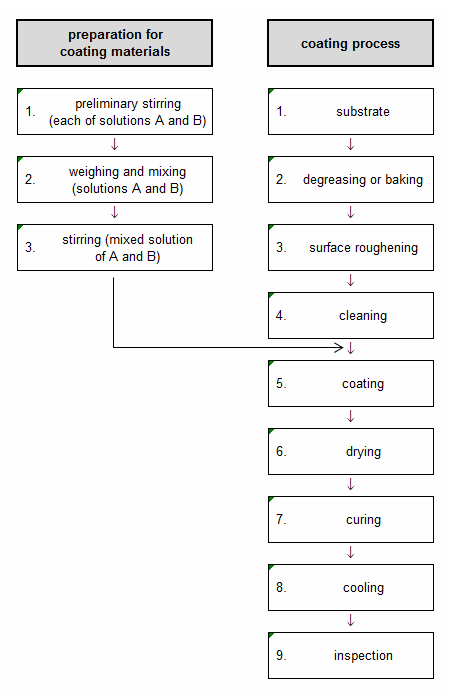

SDS (Safety Data Sheet) and TDS (Technical Data Sheet) of Silicera Coat 8011 are available.

If you need to download it, please click "download".

We propose you the most suitable coatings according to the applications and the purposes you need, such as non-stick, slippage, durability and so on.

Please feel free to contact to us for coatings.