Ceramics Manufacturing: Focus on Ceramic Structural Materials (Cylindrical Rods) for Rotational and Sliding Components

Ceramics Manufacturing: Focus on Ceramic Structural Materials (Cylindrical Rods) for Rotational and Sliding Components

- JP

- EN

Features of Our Ceramic manufacturing

Integrated Manufacturing System

We deliver ceramic structural materials through a consistent manufacturing system, from raw materials to finished products with high-precision machining.

We manufacture structural materials in alumina ceramics, zirconia ceramics, and silicon carbide ceramics.

Our alumina ceramics are available with purity levels of 92%, 96%, and 99.5%.

We are also a kiln manufacturer, utilizing our own patented kiln technology.

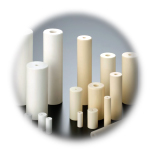

Focus on Cylindrical Rod-Shaped Ceramic Structural Materials

Our company focuses on cylindrical rod-shaped ceramic structural materials. We specialize in rotational and sliding components such as shafts and cylinders.

We offer high-precision machining and mirror polishing tailored to rotational and sliding structural materials.

For shapes other than cylindrical rods, we collaborate with our partner manufacturers to meet those needs.

Please feel free to contact us for initial consultation

We can propose manufacturing methods and shapes tailored to your specific applications and usage requirements.

Our in-house machining of ceramics, utilizing our proprietary technology, increases in-house production rates and focuses on cost reduction. Please feel free to contact us for an initial consultation.

Track Record in Ceramic Manufacturing and Processing

Air Bearing (High-Precision Polishing Technology)

We can achieve roundness of 0.5 µm and cylindricity of 1 µm.

(Note: The achievable precision may vary depending on the dimensions.)

External Diameter Mirror Polishing

- Application

- Cost-effective solution for achieving an external diameter with Ra 0.1 or less for high-speed rotational and sliding components

- Size

- φ1.5 or larger

- Material

- 99.5% Alumina

High-Precision Machined Valve-less Pump Pistons and Cylinders

- Application

- Valve-less pump components with a grease

clearance of 5 µm or less between pistons and cylinders - Size

- φ5, φ7, φ10, φ15, φ6.34, φ9, φ12.7, φ25

- Material

- 99.5% Alumina, Zirconia Toughened Alumina (ZTA)

Thin-Walled Tubes

- Application

- Heat-resistant components (800–1000°C)

- Size

- Thin-walled pipe with dimensions φ1.4 x φ0.6 x 68L and wall thickness of 0.4 mm

- Material

- 99.5% Alumina

Secrets to Reducing Costs for Ceramic Components

**Point 1: Could you please tell us about the intended use?**

Ceramics can be processed almost as easily as metals, but they do have specific limitations. Without clear understanding of the application and purpose, the benefits of ceramics cannot be fully utilized. By knowing the intended use, we can select the appropriate ceramic material and manufacturing method, potentially reducing costs.

**Point 2: Can dimensional tolerances, geometric tolerances, and surface roughness be kept to the necessary minimum?**

Specified tolerances and surface roughness significantly impact manufacturing costs, so simplifying the shape as much as possible is crucial. Relaxing dimensional and geometric tolerances where precision is not essential can lead to cost reductions.

**Point 3: Can we borrow a sample?**

If we can borrow an actual sample of the item you have been using, we might be able to propose cost-saving measures.

For Inquiry

If you provide us with information on the application, usage, and conditions, we can propose cost-saving measures. If you have any other questions or requests, please feel free to contact us.